Aquila Build for July

JULY 2023

Continually updating with Marlin bugfix-2.1.x

What's new in this release

Version: 2.1.3d-2c

**Currently working fully, HC32 Build linked here**

This firmware is based on MriscoC's Professional Firmware for the Creality Ender-3 V2/S1.

Not much has been changed since last release; Misc. fixes and formatting, just a couple merges with Marlin which - more or less - rearranged the code, and optimizing the firmware but not necessarily to a noticeable extent.

- STM32 support 9 UARTs

- Fix hotend idle timeout checks

- Fix runout extra length

- Revert M206 Home Offset behavior

- Always use ISR for BABYSTEPPING

- Ensure BLTouch deploy in HS Mode

- MString helper class

- Tramming Wizard starts a bit better

- Mesh insets now save after restarting

- Runout icon indicator over the Extruder flow dashboard icon

- Dashboard Speed percentage also flashes speed in mm/s intermittently

- Enhanced Gcode preview --- Preview QR code removed

- Improved 3D/BL/CR-Touch auto leveling

- Multiple Probing is now Extra Probing

- Improved UBL Mesh viewer

- Bed Tramming Wizard --- Find average or absolute values

- New C35 custom g-code to launch Bed Tramming Wizard

- Added toolbar option for parking head.

- Force axes home to allow parking at pause

- Raise Z when printing is aborted

- Fix a possible bug with filename drawing in printing page

- Fix Crash after removing SD card

- Added Creality Cloud Support

- Adjust encoder knob speed rates

- Fix stepper motor noise

- Several minor bug fixes and Misc. optimizations

- and many more fixes from latest Marlin's bugfix 2.1.x

Modifications in Source Code (for custom builds):

- TJC support to enable preview and grid mesh viewer

- Added Creality CV laser module support with automatic file type detection

Note 1: Due to lack of flash memory space in the Aquila's GD32/N32|F103RCT6 some features had to be disabled in the ProUI of UBL and BLT versions, including, but not limited to: TBA.

Note 2: The latest releases are promoting UBL versions over ABL (BLT - BL Touch), but ABL/BLT versions will be available. MPC autotune is available for the hot-end as a replacement to PID autotune.

This is a universal firmware that has been optimized and enhanced for both the Voxelab Aquila and Creality Ender 3 V2/S1. This firmware has also been developed to include support for HC32F460 chips (aka H32) which is included in some Aquila X2 and C2 models.

(However, it should be noted that it may not yet be fully available for "H32" labeled printers having the monochrome 12864 LCD screens).

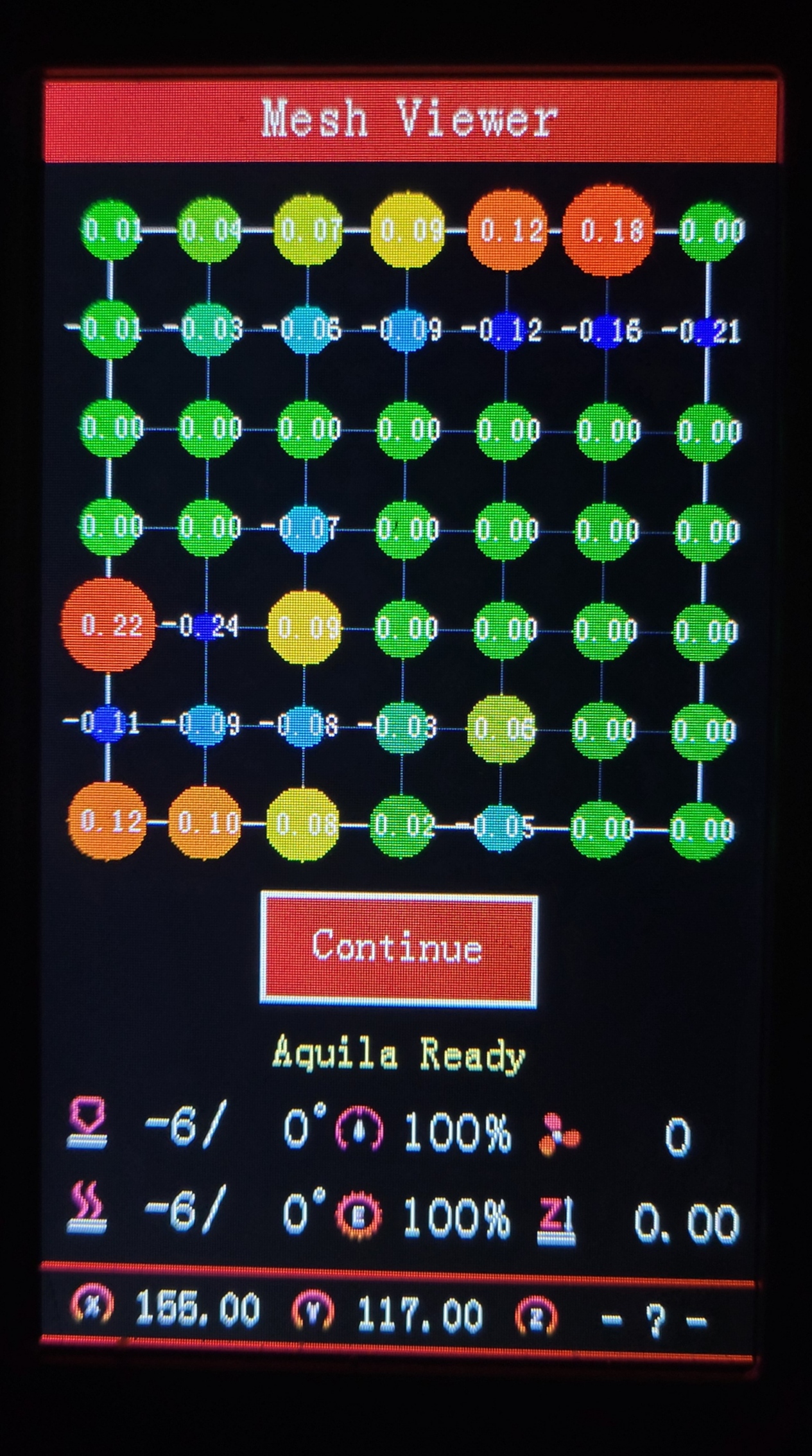

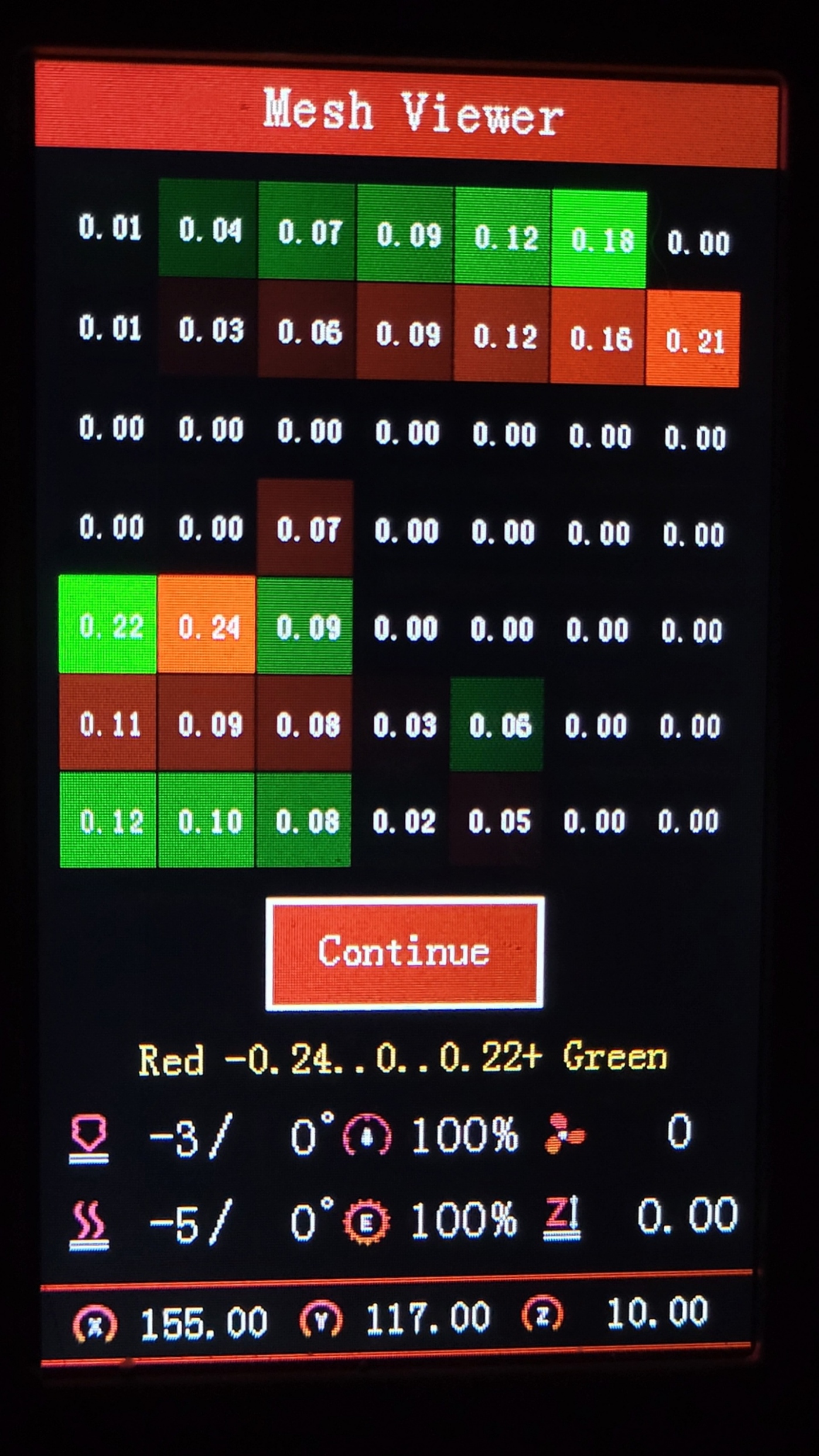

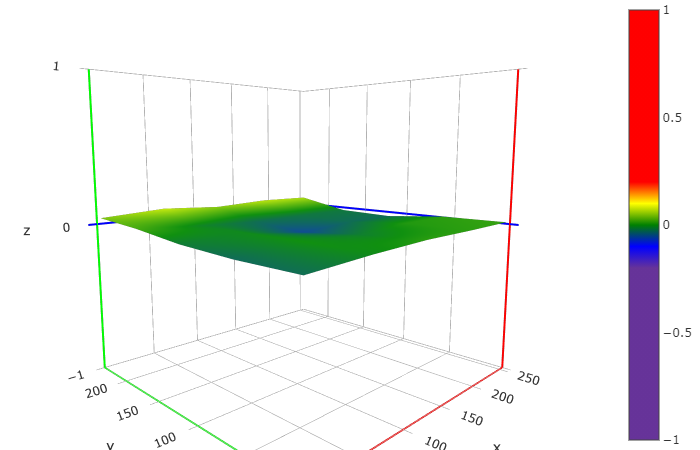

This shows the two types of meshviewer as an example

The newer colorful one has a more rainbow like characteristic

Versions

- [ _Default-NP ]: Use if you have a near stock machine Default No Probe

- [ _MM ]: Create a bed mesh without an auto bed probe Manual Mesh Bed Leveling

- [ _BLT ]: Use if you have a CR/3D/BL-Touch level sensor installed. Bilinear Auto Bed Leveling

- [ _UBL ]: Similar to both MM and BLT - with more options and the ability to view the mesh Unified Bed Leveling

You can download the firmware's latest files from the Assets at the bottom of

the release page.

UBL Information

Binaries with UBL in their filename are similar to the bilinear leveling of BLT, but with extra features to provide users with more control and information. There are multiple guides about UBL, it's recommend reading about it before using this type of leveling system.

- https://all3dp.com/2/marlin-ubl-unified-bed-levelin-simply-explained/

- https://www.3dmakerengineering.com/blogs/3d-printing/unified-bed-leveling-marlin

- https://hackaday.com/2022/01/14/3d-printering-getting-started-with-universal-bed-leveling/

Special versions

- [ -ProUI ]

| ProUI | (ProUI ENABLED)- Toolbar, Gcode model preview, and other special features and options

- [ -NoPro ]

| No ProUI | (ProUI DISABLED)- Does not have features listed

- [ -IS ]

| Input Shaping | Only if you have means to do the initial calibration- (Requires a special breakout board)

- [ -MPC ]

| MPC Autotune | (replaces PID for hotend)

Related Information

- All firmware version types have Linear Advance enabled

- Linear Advance - M900

- Input Shaping is enabled with files ending with "-IS"

- Input Shaping - M593

- MPC is enabled in firmware files containing "-MPC"

- Model Predictive Temperature Control

- MPC has proven to be a better algorithm for keeping the nozzle temperature stable, and is also very useful for high power heaters. It does take some getting used to how it works if you are unfamiliar with it. It's recommended for advanced users, so stick to the default PID versions, especially if your printer is relatively stock

Firmware features

- Universal Marlin Support

- - Support for Model predictive temperature control "MPC"

- - Support for Linear Advance

- - Support for Input Shaping

- DWIN / DACAI / TJC / SYNWIT display support

- Up to 300°c Hotend

- Improved support for Manual Mesh and CR/3D/BL-Touch

- Manual and Probe Assisted bed tramming

- Tramming Wizard for Auto Bed Leveling versions

- Calculate corner values of the bed, for easier bed tramming

- Set Bed Screw Inset to easily find each corner

- Editable physical dimensions (X/Y bed size and Z height)

- Selectable mesh point grid from 3x3 to 9x9

- Mesh editor for fine tuning Mesh Points

- Improved Mesh viewer (two types of viewers)

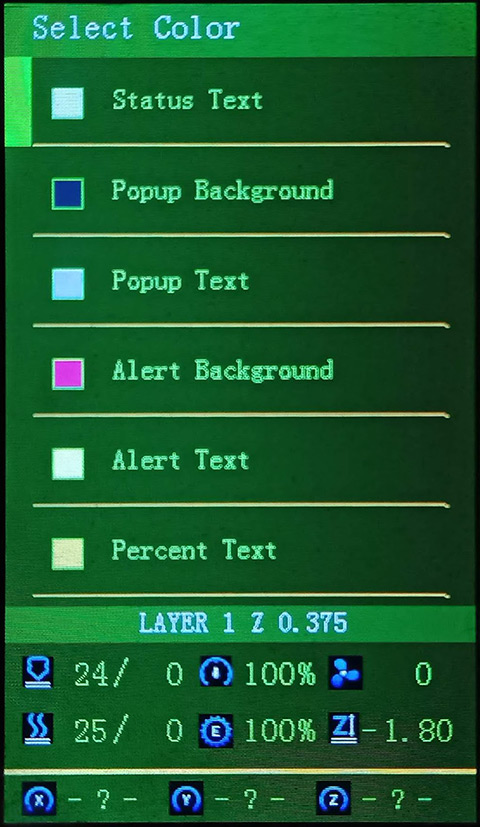

- Customizable Color theme

- Long filename support with scroll

- Baby Z-Stepping

- Probe Stow/Deploy/Reset menu items

- M48 Probe Test to Probe Settings menu

- Firmware Retract: adjust retraction settings while printing

- Filament management - Advanced pause features

- - change filament mid-print (park head/unload/load)

- Configurable park-head position (default x=0 y=220 z=40)

- Home axes after disabling motors

- Configurable Z feed rate

- Live move for all motors

- Support for S-curve Acceleration

- Restart printer menu item

- Allow invert direction of the extruder

- Support for filament runout sensor

- - Selectable runout filament sensor active state (LOW/HIGH/MOTION)

- - Editable runout distance

- Support for SD card extension (Auto-mount menu item)

- PID settings menus with viewable temperature plot graph

- - Able to view Bed or Nozzle temp on a graph during printing

- Lock screen

- Customizable pre-heat functions

- Enable/disable encoder beep/tick sound

- Preview g-code thumbnail (use this guide)

- New print done screen

- Two decimal positions for axis coordinates value

- Z-Offset wizard

- Editable minimum extrude temperature

- Turn off the LCD and Adjustable Brightness

- - LCD Timeout - Automatic turn off (Screen Saver)

- Individual axis homing

- Enable 250000 or 115200 bauds

- Power failure / power-loss recovery

- Enable/Disable Adaptive Step Smoothing

- Z-Offset icon blinks to indicate active mesh leveling

- Live End-stop diagnostics

- Printcounter and Statistics

- Toolbar with 11 configurable shortcut actions.

Octoprint bed visualizer support

More info on the Wiki pages

Requirements

Compatible main boards with the following chips:

- GD32F103RCT6

- N32F103RCT6

- Creality V4.2.2

- Creality V4.2.7

- STM32F103RET6 *some versions may not fit into RCT6

- BTT SKR Mini E3 V3 / V2

- STM32F401RC / STM32G0B1RE / STM32F103RE

Compatible LCD screens:

- A DWIN color display with encoder knob

- For using ProUIONLY DACAI, TJC, or SYNWIT displays may be used if enabled

- The following Touch or legacy monochrome screens are not supported by ProUI:

- Aquila Pro / D1 / C2

- Ender-3 / Pro

Firmware files not yet posted under Assets may be available at a later time.

Feel free to make a request for anything specific.

You can still use this source code to compile firmware for other printers, but they will not be able to use the Professional User Interface. You may also modify your printer to meet these requirements.